Description

The Senix ultrasonic level sensor measures distance to the surface of water, allowing accurate measurement of water level.

As part of an Observant system, the device can be used to:

- Display current and historical water level.

- Trigger alarms on preset high or low water levels.

- Automate pump operation to keep a tank or other water storage full.

|

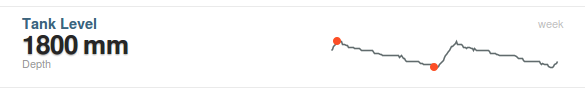

Observant Global view of water level data from the Senix ToughSonic sensor: |

Applications

Typical applications are:

- Water level monitoring in tanks,

- Water level monitoring dams,

- Water level monitoring turkeys nests*,

- Water level monitoring channels.

*Australian a small earth dam adjacent to, and higher than, a larger earth dam, to feed water by gravity to a cattle trough, etc. — Collins English Dictionary

Supported Models

Senix 13ft/4m Ultrasonic Level Sensor for Tank Kit: Item 01463

Senix 13ft/4m Ultrasonic Level Sensor with 2m Bare Ends: Item 00760

Description: Senix ultrasonic level sensor with maximum depth range 4.3 meter. Rugged, small form factor, non contact level sensing ideal for all water level applications: tank, dam, channel, bay.

Connection to Field Unit Ports

| Field Unit | Port | Interface cables and Connectors |

| C3+ | RS485 | Sensor supplied with a 4-pin connector appropriate for C3+ RS485 port |

| Solo+ | Serial & 4-20mA | Sensor supplied with a 4-pin connector appropriate for serial port |

Bare Wire Connections

In advanced installations, the sensor's bare wires can be connected to a port directly:

| Port Terminal | Sensor Wire Colour |

| + | Brown |

| A | Yellow |

| B | Grey |

| Ground | Blue |

* Note when connecting a via the Solo adaptor the wires will be + Brown, A White, B Blue & G Black

Installation

For a detailed illustrated guide, see Installation Guide — C3+ Tank Level Monitoring Kit or Installation Guide — Solo+ Tank Level Monitoring Kit.

These notes must be observed when installing the sensor. Failure to observe them can result in inaccurate or erratic measurement of the water level.

- The sensor must be mounted facing directly downwards, with an unobstructed view of the water surface

- The sensor must be mounted away from the tank wall or any other obstruction. Clearance from the sensor to the tank wall must be a minimum of 15% of the tank height. For example, if mounted in a tank whose total height is 3m (9ft10in) then the sensor must be mounted at least 45cm (18in) away from the tank wall.

- Due to the minimum distances that the sensors can accommodate, with the Tank Kit, the bottom of its sensor should be no less than 4" from the highest level to be measured.

- The Tank Kit requires a hole of 2” (50mm) in diameter

Configuration

For new customers, see how to Sign Up for the Observant Global Software Platform with a C3+ Tank Level Monitoring Kit.

If you already have an Observant Global account, remember to add your new tank kit to your portfolio as described in Adding New Equipment.

Manuals, Links and Downloads

Manual

A detailed manufacturer's user manual may be found here.

Relevant Articles

- Installation Guide — C3+ Tank Level Monitoring Kit

- Hardware Video — Observant C3™ Tank Level Monitoring Kit — Installation

- How to Sign Up for the Observant Global Software Platform with a C3+ Tank Level Monitoring Kit

- Managing Tank Level Kit Settings

Downloads

OBS-USR-M007-R3, C3+ Tank Monitoring Kit Installation Guide, is available online for printing and downloading.

Sensor Maintenance

When mounting the sensor, ensure that the face is pointed perfectly vertical at the water to minimize any echos that may disrupt the readings. This is paramount for accurate readings and should be checked if the unit or tank has encountered any movement for whatever reason.

Ice, dirt, mildew, cobwebs and other environmental material buildup can block the sensor face, which can prevent the ultrasonic soundwaves from being transmitted or received. Additionally, the ingress of contaminants, such as water, can affect sensor function.

Ideally, every 6 months, check and clean the face with alcohol or a mild cleaner, as water and condensation may cause this coating build-up on the level sensor. DO NOT use solvents such as acetone.

It is also best practice to check your sensor cable and ports at the same time for good connection, along with any kinks or broken wires that may have occurred.